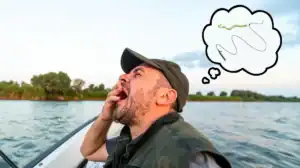

There are several key elements that need to be thought out when preparing to renovate an old boat. It takes time and a notepad is essential. Having a couple of “handy” fishing buddies is also critical. We had both here at Wired2Fish.

Step One

The “plan” is critical.

1. Chronicle what you have- The first thing to take into consideration is knowing what you have. Does the boat float? Does it have a solid infrastructure? Is the layout condusive to renovation? Is it wired correctly or if not does it have ways to run wire? All are keys to this project.

2. Getting a Blueprint- The Wired2Fish boat was hand picked and procurement took some time. We wanted a wide boat with a shallow draft. We wanted one that could be customized and we wanted tiller. We looked at both aluminum and fiberglass. We settled on a fiberglass Ranger Banshee 16-8 tiller.

The file photo below we obtained had a Minn Kota trolling motor with an long shaft so we knew the front deck was strong enough to support our Minn Kota 80- 24 volt Maxxum we had earmarked for this project. There were several other items we found interesting in this photo we will discuss later. Hint- Transom and livewell.

Setting the work plan was critical. The Banshee is a flats boat designed for shallow salt water. We combed the Internet for information about this boat and owners comments. All the comments we found were favorable. It had the floor space, deck space and storage we were looking for. We also knew that we could customize it based on our past experience with other Ranger Boats.

Although this boat usually is equipped with both casting and polling platforms we did not want the polling platform on a bass boat for obvious reasons. We knew we were going to have to repair several holes in the boat from the platform.

We also knew that this boat used pultruded fiberglass for strength and mounting so we felt comfortable it was the right boat for our plan.

We blueprinted the layout in 3 categories. Structural, Electrical and Functionality. We want over the boat with a fine tooth comb before the first thing was started.

3. Building a materials list. This was an ongoing process. It too was built on 3 categories, Structural, Electrical and Functional and this list included batteries, powerplant, trolling motor, electronics, and amenities. More on this later. Do not underestimate the need for stainless steel screws in multiple sizes and numbers. They are not cheap and you will go through a ton of them. The same is true with connectors.

The next stage in the process is the “Getting Started” phase and we will discuss it in Part II.