Boat buying includes checking the little things and there is no question that “fit and finish” separates the good ones from the mediocre. Simply put: A boat’s fit and finish are the details that makes the boat fit together like a fine watch. Whether it’s a piece of trim, the carpet or how the lids fit, great boat companies are precise in all areas of production. I have been around bass boats since their beginning days and the good old days are now. Boats and engines are the best they have ever been.

Setting the bar

For years, Ranger Boats has been the example for other boat companies on how to build a boat that not only looks and rides great but also incorporates the intricate details that make them a step above.

Before going on a plant tour at the Ranger Advantage Seminar some 20-plus years ago, I thought all boats were created equal; same materials, same craftsmen and same components. Boy was I wrong. Innovation both in materials and how they are laid out give a Ranger a one-piece feel.

That is not taken lightly in Flippin, Arkansas and it has been that way for over 45 years.

Building each boat like they’re building it for themselves

Instead of a just getting by with an attitude to get boats out the door, I have heard over and over again that Ranger builds their boats as if they were building them for themselves and although they are more expensive that many of the other boats on the market, there is good reason why. They don’t cut corners with the types of materials, the functionality or how they are put together.

The details

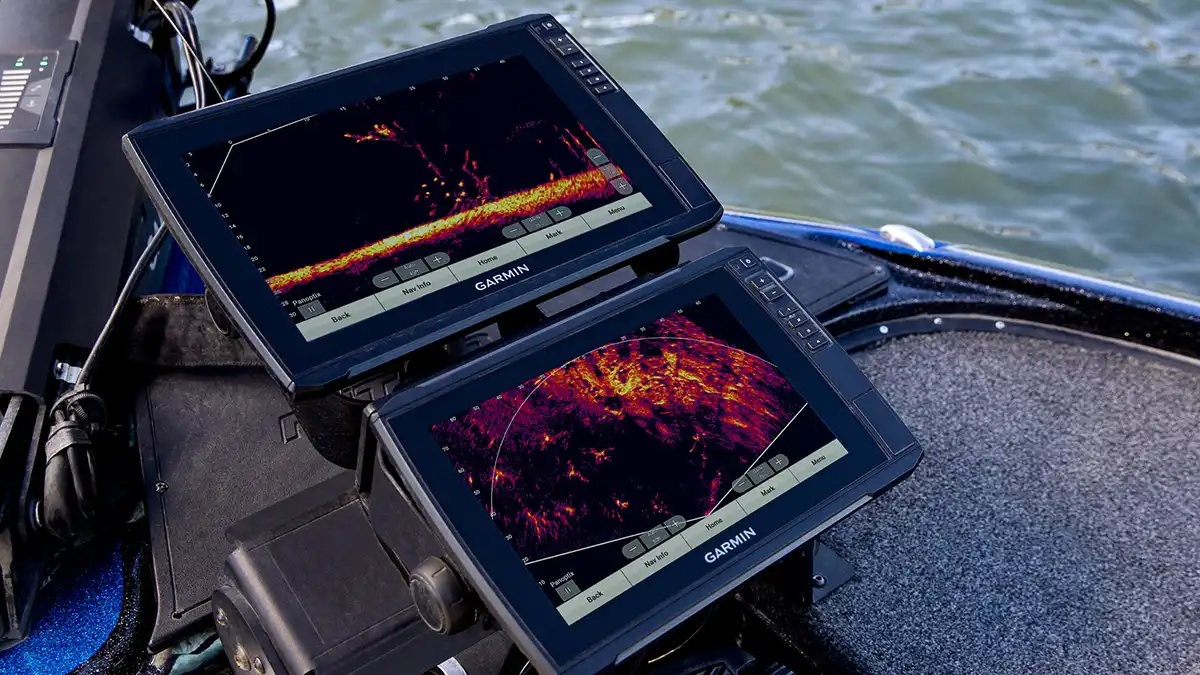

Each lid, opening and part is precision-cut to tight tolerances. A computer-assisted, high-pressure water cutter assures that each piece is perfect on fiberglass models. From the showroom to the water, Ranger wants their boats to not only look good but provide function on the water that is second-to-none.

Any boat will perform and work well in light wind, but the devil is in the details when seas get rough. A firm, stable ride is an earmark of that Ranger quality.

Padded deck in the front of the Ranger is something you cannot see but you sure can feel it and it makes long days on the water more tolerable and easier on the back. Combined with a recessed trolling motor foot pedal, it works magic for the angler who stands all day.

Construction and contours

The construction is solid, the look is premier and the set up took years of listening to anglers and boaters on what they wanted. Ergonomic consoles and steps, tool holders, recessed foot pedals, pultrusion fiberglass backed supports and transoms for items like trolling motors, hotfoot and engines are well thought out. They even back cleats and other parts that can be wallowed out after years and year of use. Contoured edges are the rule and no sharp or rough angles give each Ranger a space-age appeal.

Clean and tight is more than a sales pitch

Fit and finish is much more than marketing or a sales pitch. It’s just what they do and honestly, while writing this I tried to remember any construction failures I ever had when I owned one. All of the 15 or so Rangers I have owned never had a single issue. I am sure one might slip through the cracks but fortunately I never experienced that.

From the front of the boat to the transom, small details overlooked by many like gunnel height for better flipping and pitching, accessory holders in the front and at the consoles and spacious and easily accessible rod and tackle storage with ventilation are just part of it. It doesn’t matter if your boat choice is fiberglass or aluminum: Tight engineering practices produce a better boat. Even grab handles and foot rests add to the final product.

Cosmetics do matter

Cosmetics do not add to the functionality but add value for resale and overall appearance. Ranger has taken branding to a new level with raised lettering and high-glass logo placement. Lids are reinforced with a patented vacuum lid process and lift assist cylinders are strategically mounted and reinforced to prevent failure and assure stability even in the wind. Nothing is worse than having a lid fall on your favorite rod or smashing your finger.

An education in boat building

Sitting with the folks at Ranger is an education in boat building and since many of their best and brightest have been there for years, the tradition of “building legends” will hopefully continue. The innovation in materials, new options and better functionality are all blended together in Ranger Boats. Just like electronics and lures, there is something new every year. I don’t see that changing.